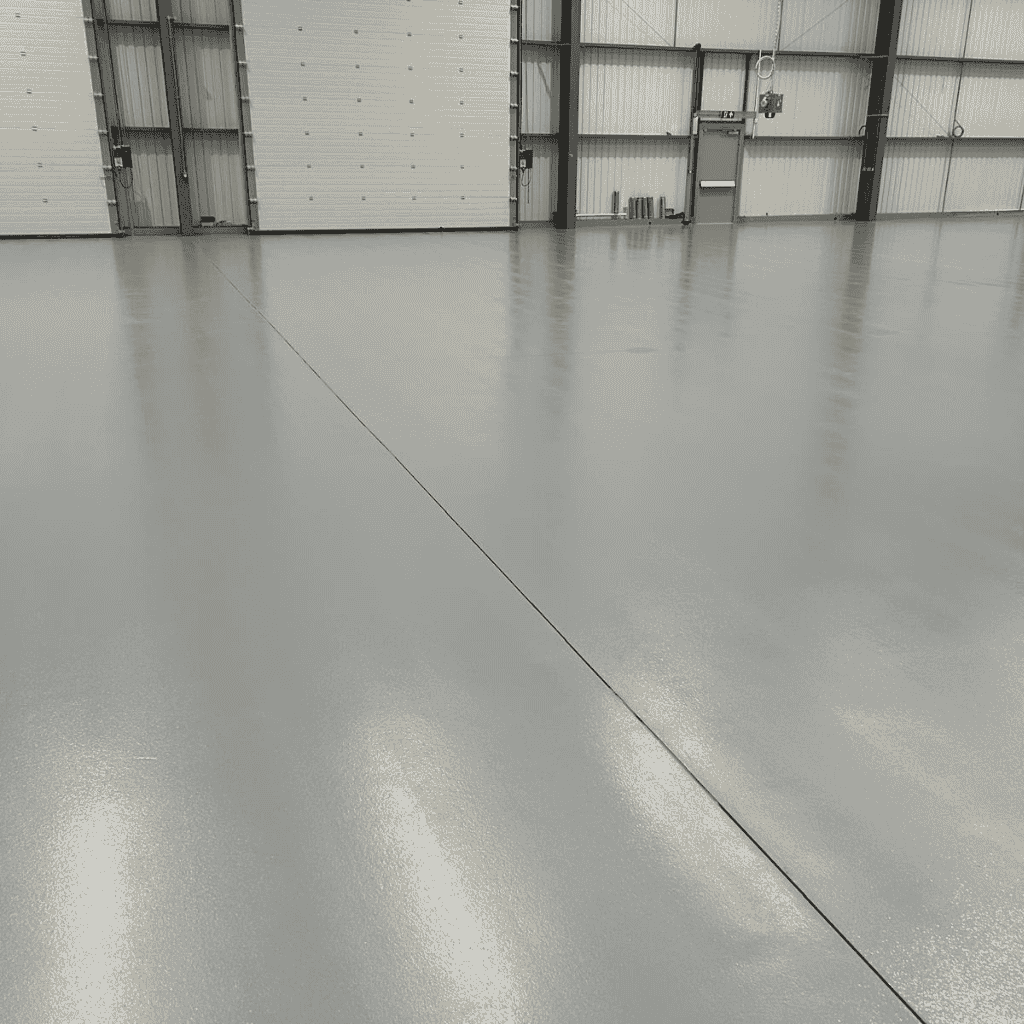

MONARCH RESIN FLOORS TRANSFORMS SUNDERLAND WAREHOUSE WITH MONARGRIP SYSTEM

When it comes to creating durable, slip-resistant flooring solutions, Monarch Resin Floors is a name trusted by architects, project managers, and business owners across the UK. Recently, our team had the opportunity to deliver an exceptional flooring solution for a new client in Sunderland, showcasing the versatility and reliability of