Floor joint repair is an essential part of maintaining durable, safe, and hygienic flooring in industrial and commercial environments. Over time, concrete joints can crack or break down under heavy traffic or thermal movement. Our Monarjoint resin system provides a semi-rigid floor joint repair solution that helps reduce edge damage.

As expert resin flooring contractors, Monarch Resin Floors deliver reliable resin floor jointing and industrial floor joint repairs across the UK. Offering polyurethane jointing systems depending on the application.

When compared with traditional mastic or silicone joints, our resin jointing systems provide far greater impact resistance, load-bearing capacity, and chemical durability. They are the preferred choice in sectors like food and drink flooring, warehouse flooring, pharmaceutical and laboratory environments, and manufacturing flooring.

Monarjoint is a semi-rigid floor jointing system designed for industrial resin flooring and concrete floor repair where durability and flexibility are both essential. It provides long-term protection to expansion joints, day joints, and crack repairs by allowing for controlled movement without edge breakdown.

As part of Monarch’s floor jointing and resin floor repair services, Monarjoint delivers superior performance compared with mastic or silicone sealants. It prevents spalling, supports heavy traffic from forklifts and pallet trucks, and maintains a clean, hygienic surface in demanding industrial environments.

Monarjoint resin systems are engineered for warehouse flooring, manufacturing facilities, and food-grade flooring applications where resistance to impact, vibration, and chemical exposure is critical. Each installation is carried out by Monarch’s experienced resin flooring contractors using materials sourced from trusted manufacturers including KDR Resins, Vebro Polymers, and RESDEV.

This industrial joint repair system meets FeRFA standards for performance and chemical compatibility, offering an ideal solution for concrete joint reinstatement, polyurethane joint repair depending on the substrate and operational requirements.

| Property | Specification |

|---|---|

| Type | Two-part polyurethane resin jointing compound |

| System | Semi-rigid resin joint repair for industrial and commercial flooring |

| Components | Part A (Resin) and Part B (Hardener) mixed 1:1 by volume |

| Appearance | Viscous liquid, various colours (Part A); brown liquid (Part B) |

| Density (20 °C) | ~1.44 g/cm³ (Part A); ~1.23 g/cm³ (Part B) |

| Viscosity (20 °C) | High (Part A); ~27 cP dynamic (Part B) |

| Flash Point | > 60 °C (non-flammable) |

| Solubility | Immiscible in water |

| Cure Time (20 °C) | 8–12 hours (typical) |

| Recommended Application Temperature | 5 °C – 30 °C |

| Load Bearing | High load tolerance suitable for forklift and pallet traffic |

| Chemical Resistance | Resistant to oils, fuels, mild acids and alkalis |

| VOC Content | 0 % |

| Shelf Life | 6 months (unopened containers, stored between 15–25 °C) |

| Packaging | Supplied in matched Part A and Part B units |

| Colour Options | Standard grey and neutral tones; custom RAL colours available on request |

Disclaimer: The information above is provided as a broad general guide for the Monarjoint product. Please refer to the latest Technical Data Sheet (TDS) and Material Safety Data Sheet (MSDS), and consult our technical team before specifying or ordering. Manufacturing developments may result in changes before this website is updated.

What is floor joint repair?

Floor joint repair is the process of reinstating or replacing damaged concrete expansion joints to restore surface integrity and prevent edge breakdown. This is essential in industrial resin flooring and warehouse flooring where heavy traffic or thermal movement can cause cracks and surface failure.

Why is floor jointing important in industrial flooring?

Floor jointing allows a concrete slab to move without cracking or deforming. In industrial resin floors, properly installed joints absorb vibration and prevent chipping around the edges, maintaining a safe, level, and long-lasting surface.

What materials are used for floor joint repair?

Resin jointing systems such as polyurethane compounds are preferred for industrial floor joint repair. They provide higher load-bearing strength and chemical resistance than mastic or silicone sealants. Products like Monarjoint are examples of semi-rigid resin joint systems designed for this purpose.

Can floor joints be repaired without replacing the whole floor?

Yes. Using resin joint repair compounds, existing joints can be cleaned, re-cut, and refilled without the need to remove surrounding resin flooring. This method reduces downtime and cost while restoring structural performance.

Where are resin floor joints commonly installed?

Resin floor jointing is used in manufacturing flooring, food and drink flooring, warehouse flooring, and factories. These environments demand durable, hygienic, and chemically resistant surfaces.

How long does a floor joint repair take to cure?

Curing time depends on the material and temperature, but rapid-cure resin joint repairs typically allow traffic within 12–24 hours. For larger areas or heavy plant zones, a full cure may take up to 48 hours.

What is the difference between rigid and semi-rigid floor joints?

Rigid joints provide maximum strength but minimal movement tolerance, whereas semi-rigid resin joints offer the balance of flexibility and support needed for industrial environments. Semi-rigid polyurethane systems such as Monarjoint are ideal for movement joint repair and floor crack reinstatement.

Are resin floor joints food-safe?

Yes, polyurethane floor jointing systems are commonly used in food-grade flooring and meet hygiene standards when installed by certified resin flooring contractors. We give free technical advice as members of The Resin Flooring Association.

This is just a simplified step by step guide to help you visualise the process behind floor jointing when considering a resin floor. We would be happy to provide some more detailed information to anyone who would like to know more about the resin floor jointing process.

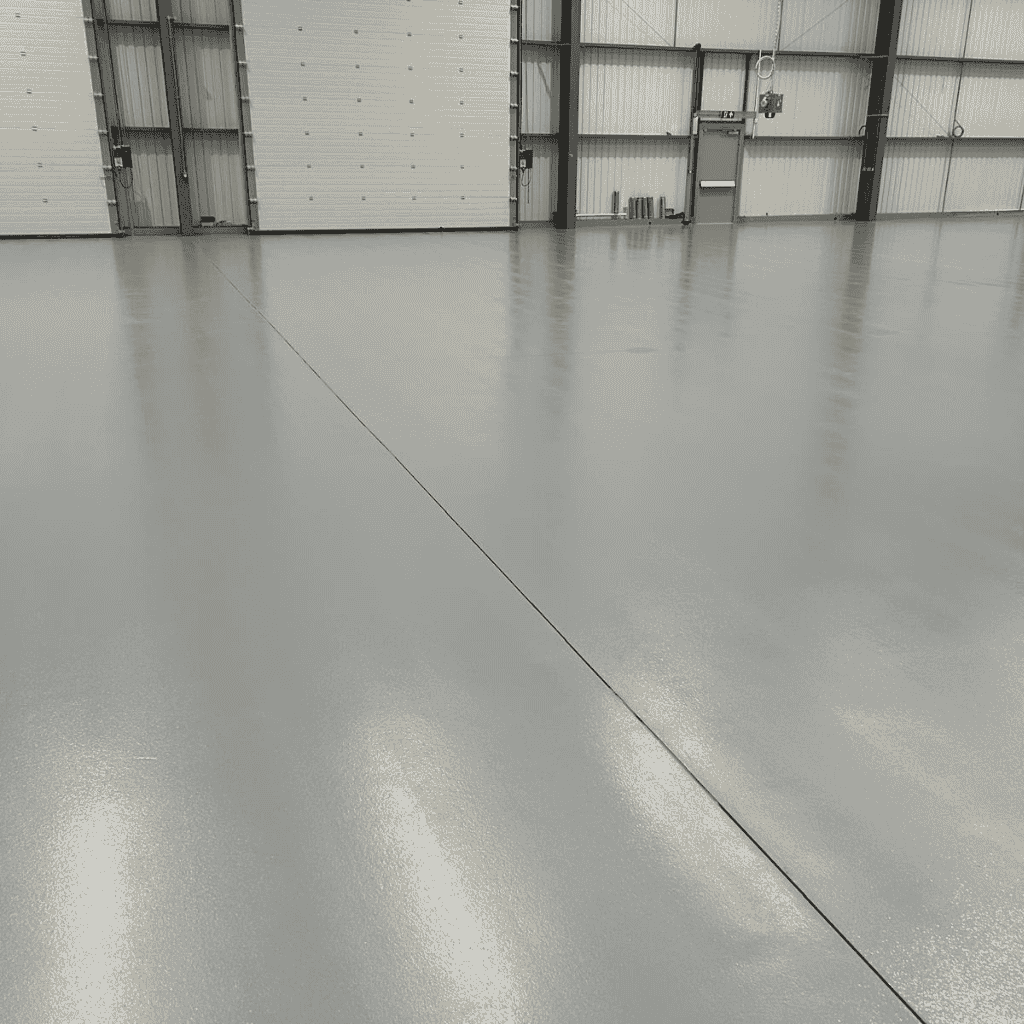

At Monarch Resin Floors, we supply and install floor jointing systems such as Monarjoint for a wide range of industrial and commercial flooring environments. Our expertise covers resin joint repairs, floor expansion joints, and seamless transitions between concrete slabs and resin surfaces. These systems protect floor edges, reduce cracking, and extend the life of your flooring.

From warehouses and manufacturing facilities to food production areas and aircraft hangars, our skilled team ensures every installation meets exact site demands. Based in Derbyshire, we serve clients across Sheffield, Leeds, Manchester, Nottingham, and throughout the UK.

For expert advice or to request a free site survey, get in touch with us today. We can also advise on related services including resin floor repairs, industrial resin flooring, and resin floor preparation to ensure a complete and durable finish.

We would love to speak with you about your resin flooring project.

Feel free to reach out using the below details or fill out the contact form and a member of our team will get in touch with you within 48 hours.

We never pass on any of your information to third parties and will only get in touch about the flooring project your enquiring about.

We never pass on any of your information to third parties and will only get in touch about the flooring project your enquiring about.